Cobot applications

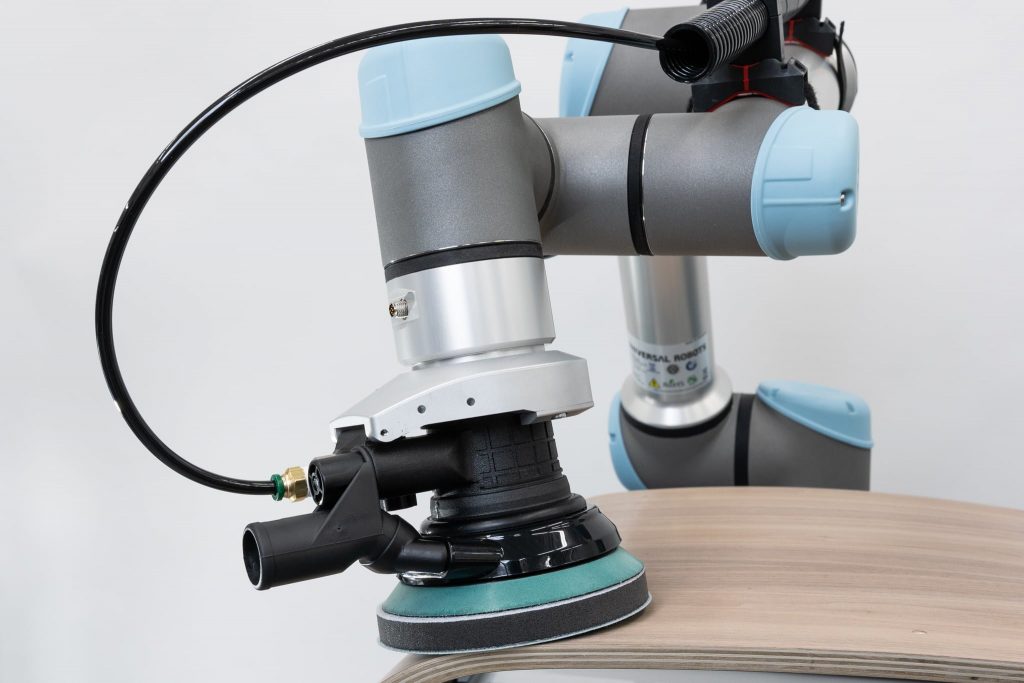

Sanding and polishing

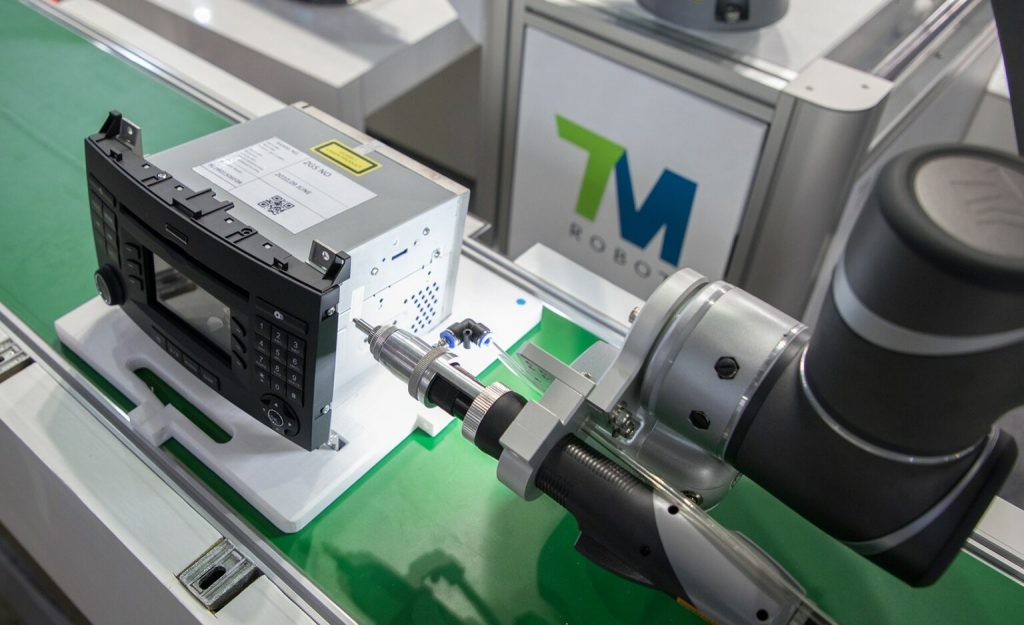

Screwing

Pick-and-place

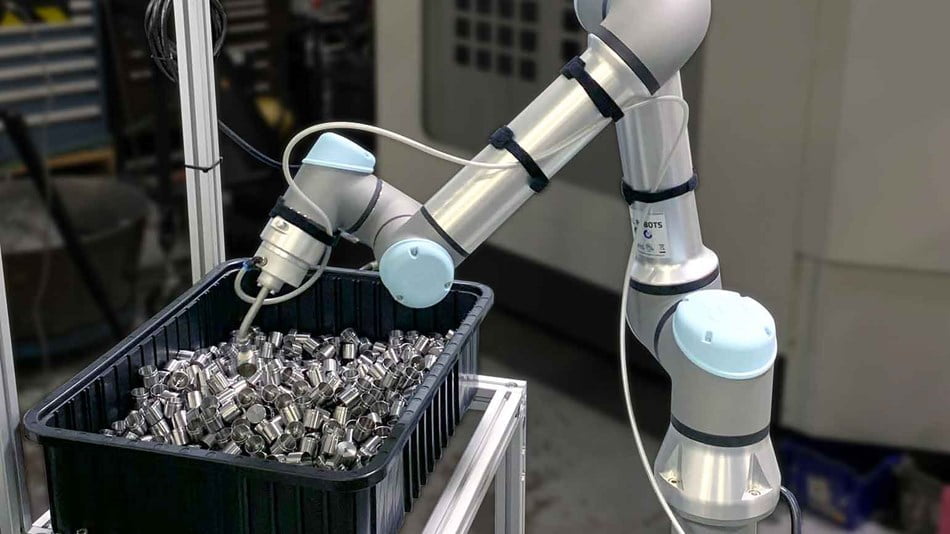

Bin Picking

Bin picking is a complicated pick-and-place application. In bin picking, objects are offered to the robot in an unstructured way in bulk. This means that the robot cannot always go to the same point to pick up the object. Thanks to smart software and vision technology and sensors, the robot can locate objects and pick them up one by one.

Machine Tending

Palletizing

Quality testing and inspection

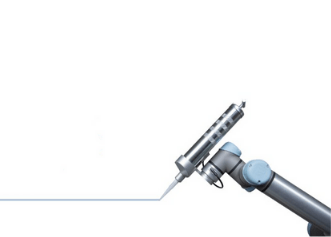

Gluing and sealing

Gluing and sealing are excellent tasks for a cobot. A sealant or glue syringe is mounted on the end of the cobot. The cobot moves along the desired path and distributes the glue or sealant evenly.

Sanding and polishing

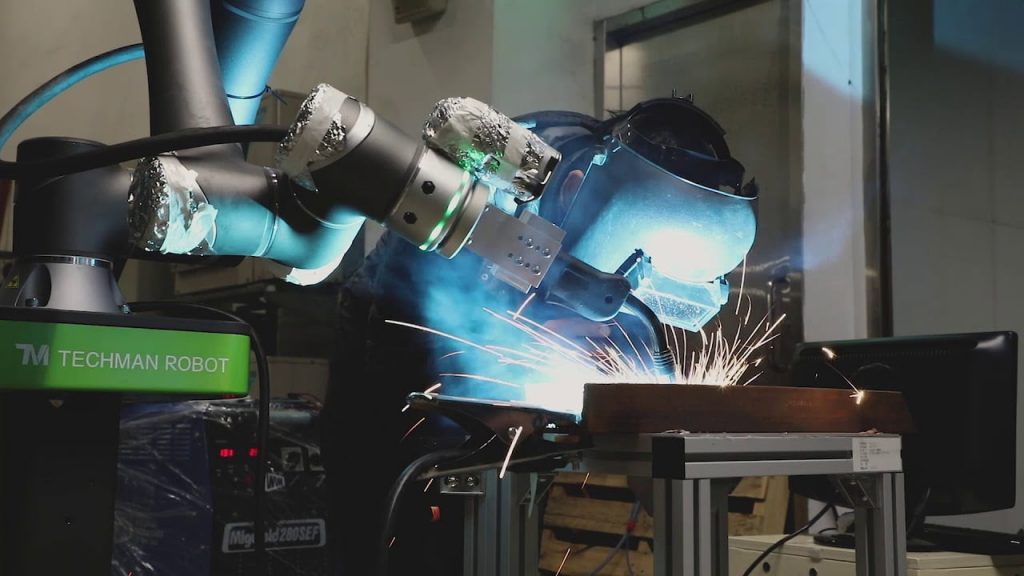

Soldering and welding are tasks that must be performed with the utmost precision. Cobots are more precise than humans and will therefore deliver more consistent quality. Cobots can solder and weld in various applications. Think Mig/Mag, Tig, spot welding, arc welding, ultrasonic welding and plasma welding.